Production

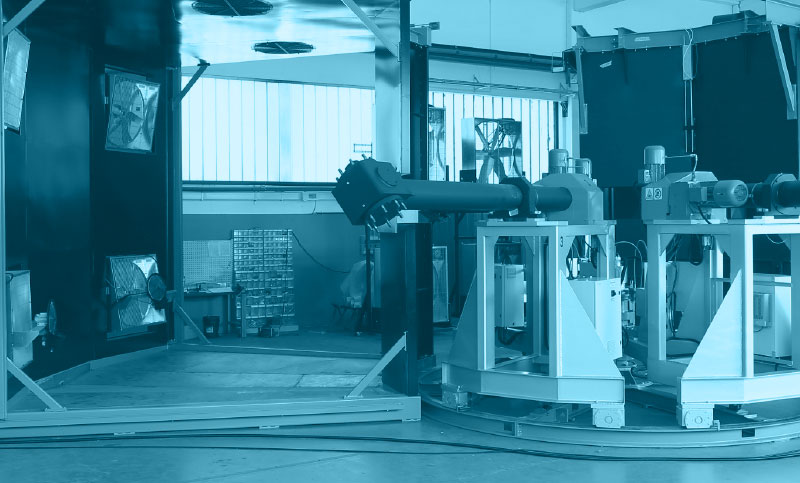

SHUTTLE

MACHINE

Description

This machine is perfect for companies in need of a more compact rotational moulding machine, thanks to its rectangular shape.

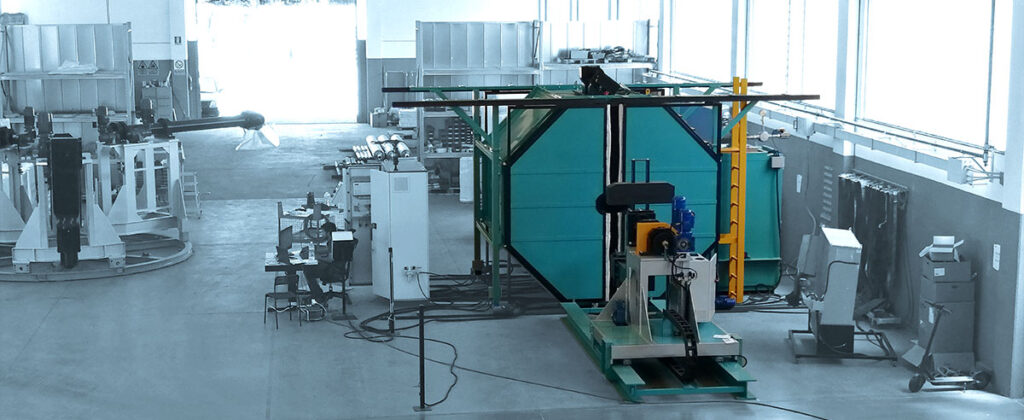

The Shuttle Machines, equipped with a stable central oven and 2 carriages that enter and exit the oven alternately, allow for loading and unloading of different moulds, offering greater flexibility and multiple production capabilities.

While one carriage is in the moulding phase, the other is in the cooling and disassembly phase. Customers with smaller production needs may start with a single carriage and later add a second one.

Like the Carousel Machines, the Shuttle Machines also boast a significantly reduced heat dispersion impact compared to the past, thanks to the use of a double material layer (one microporous and the other made of super compact felts) based on pyrogenic silica as thermal insulation for the oven, allowing for greater energy efficiency of the rotational moulding process, reducing operating costs and contributing to a more sustainable production.

The main advantages of the Shuttle Machines include versatility in producing items of listcheck out the post right heresmartphone 8 inch different sizes and shapes, increased productivity due to reduced downtime, automation of maintenance tasks and automatic regulation of airflow within the arms directly managed from the operator panel.

The Shuttle Machines are ideal for companies requiring small to medium-scale production while maintaining high efficiency.

External oven temperature:

reduced by

compared to traditional rock wool insulated ovens.

Gas consumption:

reduced by

compared to traditional ovens.

Cooking times:

reduced by up to

compared to both Italian and European competitors.

Arm capacity:

up to

higher than market standards.

Standard features

• Central moulding chamber

• Configuration with 1 or 2 carriages, working and cooling stations

• High loading capacity for straight, L-shaped, and C-shaped arms

• Revolutionary thermal insulation ensuring low gas consumption

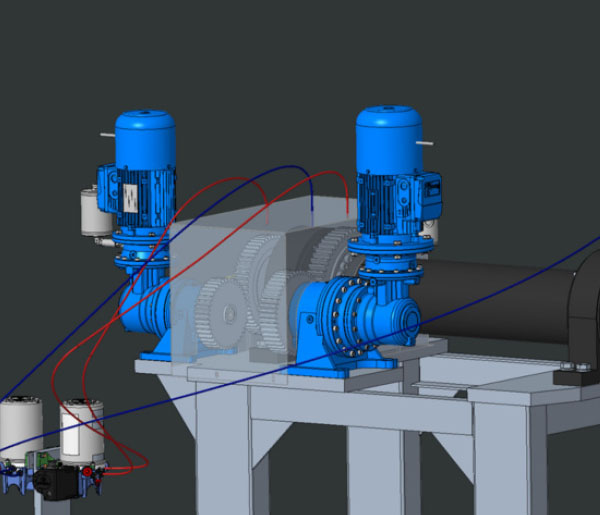

• Digital and modulating burner for optimal fuel management

• Arms with 2 or 3 air lines

• Easy to manage, user-friendly operator interface

• Safety guards with photocells and/or laser scanner

• Forced air-water cooling fans

• Ideal for small and medium production needs

Optional

OPTIONALS

AND ACCESSORIES

Loading and unloading platform, available either mobile or fixed

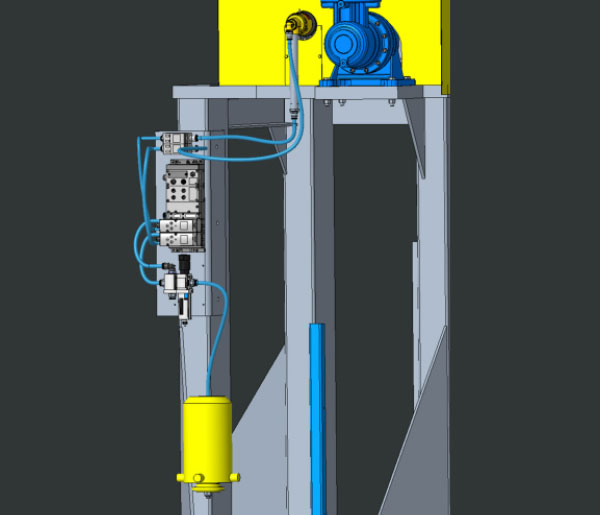

Automatic maintenance system

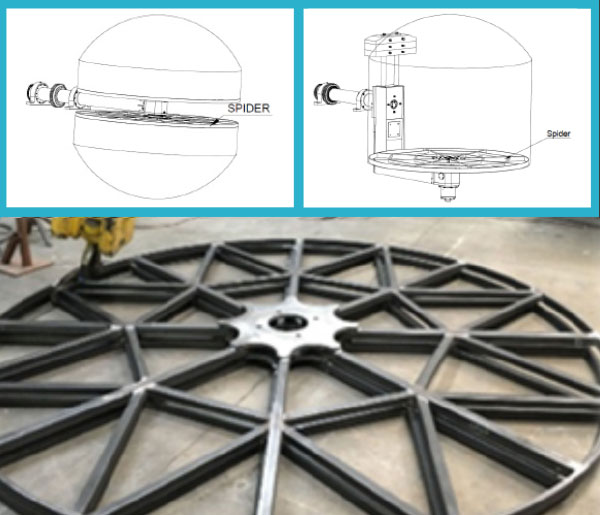

Mould-supporting arms mounted on carriage (spiders)

Dosing and feeding systems

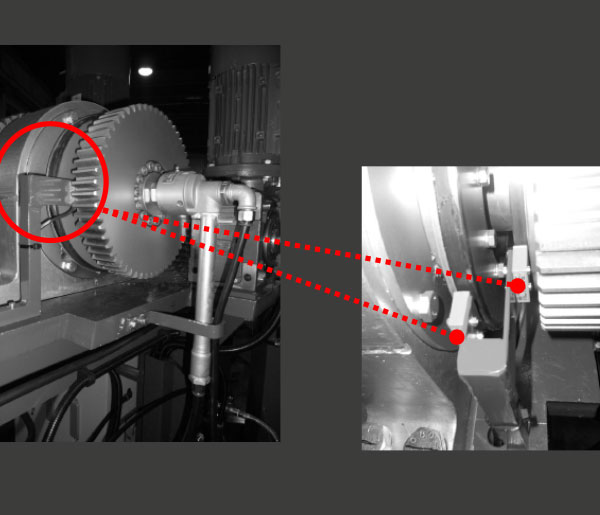

Remote airflow control system

Automatic arm positioning

Powder coloring mixers

Contact us

IPE, your solution for cutting-edge rotational moulding and innovative mixing machines.

CERTIFIED QUALITY

ASK QUESTION

CERTIFIED QUALITY

IPE ROTOMIX

Innovation Polymer Engineering: Customized and automated solutions in the world of rotational molding and turbo-mixing. Passion and efficiency for the plastics industry, from Italy to the whole world, in partnership with DP Group.

REGISTERED OFFICE

Via Giordano Bruno 8

21013 Gallarate (Va) – ITALY

OPERATIONAL HEADQUARTER

Via Olona 195

21013 Gallarate (Va) – ITALY